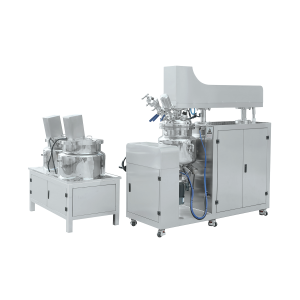

Stainless Steel High Shear Nail Polish Ho etsa Emulsifying Mixer

Selelekela:

Motsoako oa vacuum emulsifying haholo-holo o entsoe ka pitsa ea metsi, pitsa ea oli, pitsa ea emulsifying, sisteme ea vacuum, sistimi e phahamisang (ka boikhethelo), sistimi ea taolo ea motlakase(PLC ke boikhethelo), sethala sa ts'ebetso.joalo-joalo Li-emulsifiers tsa vacuum tse hlahisoang ke k'hamphani ea rona li kenyelletsa mefuta e mengata.Sistimi ea homogenizer e kenyelletsa homogenization e kaholimo, homogenization e tlase, ho potoloha ka hare le kantle ho potoloha homogenization.Mekhoa ea ho kopanya e kenyelletsa ho kopanya ka tsela e le 'ngoe, ho kopanya habeli le ho kopanya helical.Lisebelisoa tsa ho phahamisa li kenyelletsa ho phahamisa li-cylinder tse le 'ngoe le ho phahamisa li-cylinder tse peli.Lihlahisoa tse fapaneng tsa boleng bo holimo li ka etsoa ho latela litlhoko tsa bareki.

Tekheniki Parameter:

Mohlala: 10L

Enjene ea Homogenizer: 0.75KW 0-3000r/min

Agitator: 0.37KW 0-63r/min

Boemo bo ka ntle: L 1350mm * W 580mm * H 1200/1800mm

Kakaretso ea matla: mocheso oa mouoane 3KW;mocheso oa motlakase 6KW

Moeli oa vacuum: -0.09mpa

Litšebetso le Likarolo:

▲ Li-emulsifiers tsa vacuum tse hlahisoang ke k'hamphani ea rona li kenyelletsa mefuta e mengata.Sistimi ea homogenizing e kenyelletsa homogenization e holimo, homogenization e tlase, ho potoloha ka hare le kantle ho potoloha homogenization.Mekhoa ea ho kopanya e kenyelletsa ho kopanya ka tsela e le 'ngoe, ho kopanya habeli le ho kopanya helical.Lisebelisoa tsa ho phahamisa li kenyelletsa ho phahamisa li-cylinder tse le 'ngoe le li-cylinder tse peli.Lihlahisoa tse fapaneng tsa boleng bo holimo li ka etsoa ho latela litlhoko tsa bareki;

▲ Ho kopanya makhetlo a mararo ho amohela converter ea maqhubu a tsoang linaheng tse ling bakeng sa phetoho ea lebelo, e ka finyellang litlhoko tse fapaneng tsa theknoloji;

▲ Sebopeho sa homogenizing se entsoeng ka theknoloji ea Sejeremane se amohela setifikeiti se tsoang kantle ho naha se habeli.Lebelo le phahameng la ho potoloha emulsifying le ka fihla ho 4,200rpm mme botle bo phahameng ka ho fetisisa ba ho kuta bo ka fihla ho 0.2-5μm;

▲ Vacuum defoaming e ka etsa hore lisebelisoa li finyelle tlhokahalo ea ho ba aseptic.Thepa ea vacuum e anyang e amoheloa, 'me haholo-holo bakeng sa lisebelisoa tsa phofo, ho anya ka vacuum ho ka qoba lerōle;

▲ Sekoahelo sa emulsifying pitsa se ka amohela mokhoa oa ho phahamisa, ho bonolo ho hloekisa 'me phello ea ho hloekisa e hlakile haholoanyane, pitsa ea emulsifying e ka amohela ho tenyetseha ha setlolo;

▲ 'Mele oa pitsa o cheselitsoe ka poleiti ea tšepe e sa hloekang e tsoang kantle ho naha.'Mele oa tanka le liphaephe li amohela ho belisoa ha seipone, tse tiisang ka botlalo litlhoko tsa GMP;

▲ Ho ea ka litlhoko tsa theknoloji, 'mele oa tanka o ka futhumatsa le lisebelisoa tse pholileng.Mekhoa ea ho futhumatsa haholo-holo e kenyelletsa ho futhumatsa mouoane le ho futhumatsa motlakase;

▲ Ho etsa bonnete ba hore taolo ea mochine oohle o tsitsitse haholoanyane, lisebelisoa tsa motlakase li amohela litlhophiso tse tsoang linaheng tse ling, e le hore li finyelle ka botlalo litekanyetso tsa machaba.

Lintlha:

| ◉Sekoaelo sa tanka se nang le likou tsohle tsa ts'ebetso:

| ||

| Vacuum pressure gauge le valve: ho beha data ea vacuum le ho laola ho bulela le ho tima. | Material Inlet: ho monya thepa ho tloha tanka e 'ngoe ho tanka e kholo ka phala | Leseli la ho shebella: Ho bebofatsa ho shebella mosebetsi oa tanka ka hare. |

| Ho kenya linoko: Ho kenya senoko kapa ntho e nyane. | Air filter: Ho qoba moea o kantle ho kena ka har'atanka nakong ea mosebetsi. | Khalase ea mahlo le mokoti: Itloaetse hohlokomela ka hare ho boemo ba pitsa. |

| Sistimi ea ho hloekisa: Hokela bolo e bilikang ea 360°. | ||

-

Mochini o kopanyang oa hydraulic cylinder emulsion mixer...

-

Motlakase o futhumatsang bacuum emulsifying equipmen...

-

Mofuta o tsitsitseng vacuum homogenizer cosmetic mixer ma...

-

Lab vacuum emulsifier|Homogenizer Bakeng sa Litlolo

-

Ka hare le kantle ho potoloha homogenizer e...

-

Sehlahisoa sa Setlolo sa Setlolo sa Setlolo sa Setlolo H...