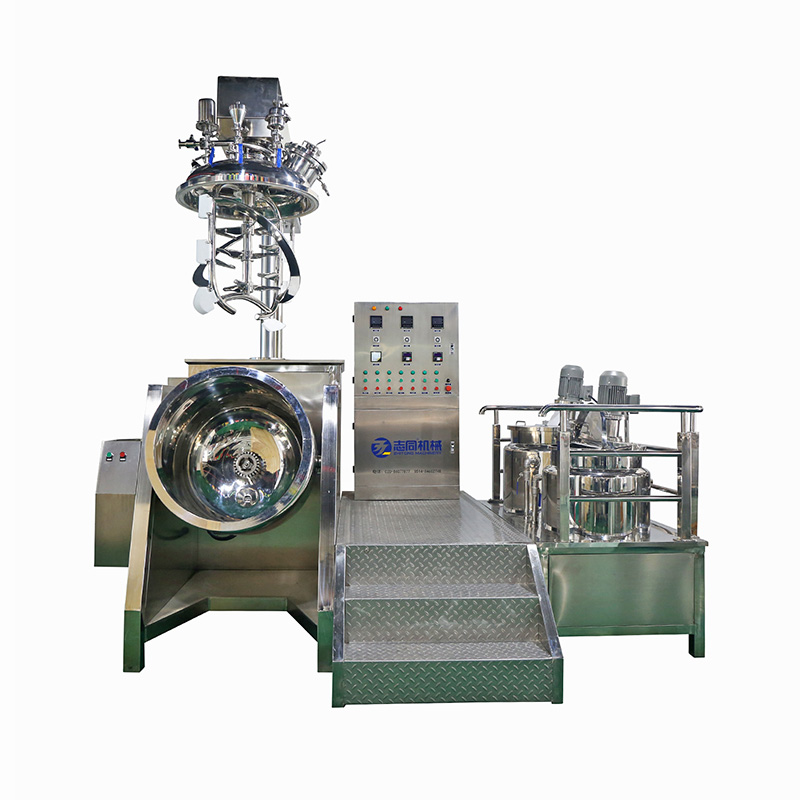

Tlhaloso ea Sehlahisoa

1.'Mele oa pitsa ea tšepe e sa hloekang e nang le likarolo tse tharo ke "interlayer" e bohareng, lera la ho kenya mocheso, 'me karolo ea ho ikopanya le thepa ke 316L, lera le bohareng ke 304 tšepe e sa hloekang ea mocheso,' me lera la ho boloka mocheso ke 304 tšepe e sa hloekang. .

2.Moralo oa sebopeho sa mochini oohle oa utloahala, khetho ea lisebelisoa e ntle haholo, le sistimi e ntle ka ho fetisisa ea emulsification.

3.Taolo ea lebelo e se nang mohato, lebelo le phahameng ho fihla ho 6000rpm, le phahameng bakeng sa lebelo la mohala oa hau oa 66m / s.

4.Ho homogeneous ho fuduha le ho tsokotsa ho ka sebelisoa ka thoko kapa ka nako e le 'ngoe.Phatlalatso ea lintho tse bonahalang, homogenization, emulsification, ho kopanya le ho kopanya ho ka phethoa ka nako e khutšoanyane.

5.'Mele oa pitsa ea tšepe e sa hloekang e nang le likarolo tse tharo ke "interlayer" e bohareng, lera la ho kenya mocheso, 'me karolo ea ho ikopanya le thepa ke 316L, lera le bohareng ke 304 tšepe e sa hloekang ea mocheso,' me lera la ho boloka mocheso ke 304 tšepe e sa hloekang. .

6.Moralo oa sebopeho sa mochini oohle oa utloahala, khetho ea lisebelisoa e ntle haholo, le sistimi e ntle ka ho fetisisa ea emulsification.

6.Taolo ea lebelo e se nang mohato, lebelo le phahameng ho fihla ho 6000rpm, le phahameng bakeng sa lebelo la mohala oa hau oa 66m / s.

7.Kopana le tikoloho ea hau e fapaneng ea ts'ebetso (e koetsoeng, e bulehileng, khatello e tloaelehileng, vacuum).

8.Tšireletso e feteletseng, tšireletso e habeli le ho pata, ho u fa tšireletso.

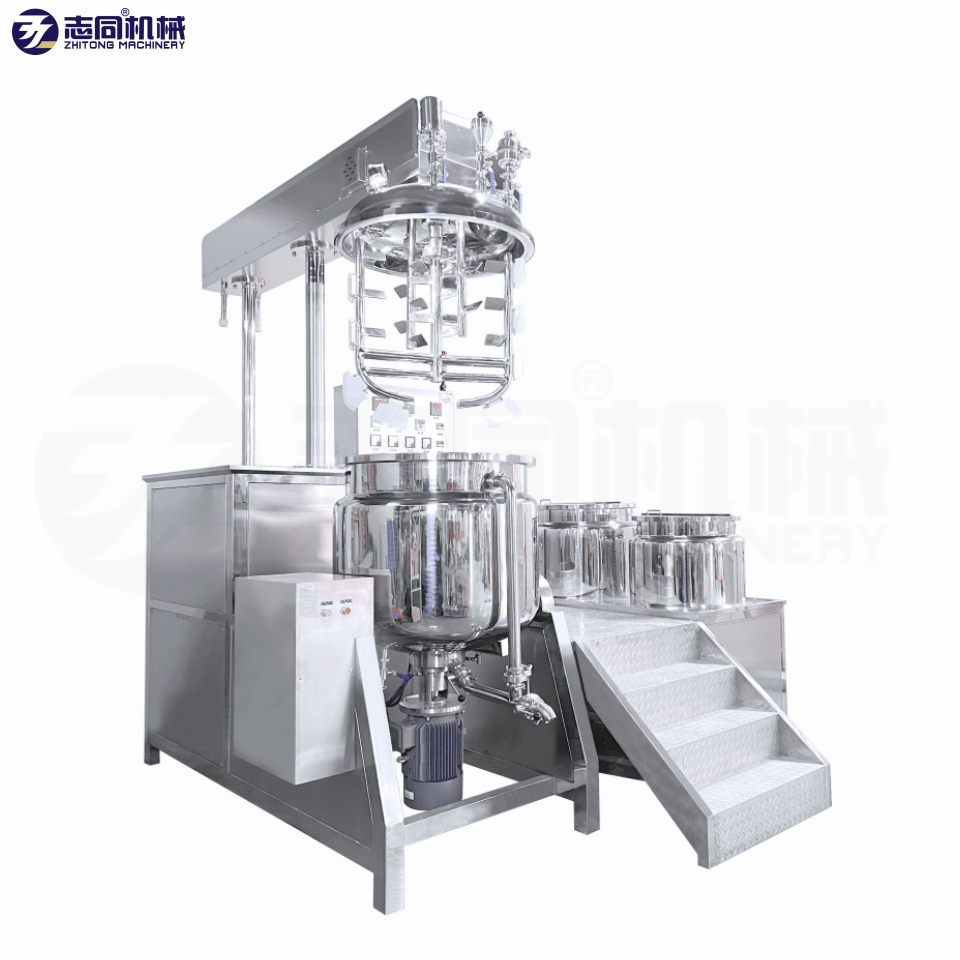

9.Foromo e susumetsang ka ntle: lebanta la spiral le hohla le ho hlohlelletsa, le fetang 2/3 e phahameng ho feta ts'ebetso e tloaelehileng;

10.Foromo e susumetsang ka hare: ho hlohlelletsa paddle, e etsang hore phallo ea metsi e be e sa tloaelehang, e le ho finyella phello e ntle ea ho kopanya.

11.Sebopeho sa ho kopanya se amohela mokhoa o nang le welded ka ho feletseng, sebopeho sa motsoako oa motsoako o hlophisitsoe ka likhato tse 45, 'me manonyeletso a ka hohle kamoo ho ka khonehang ho qoba moloko oa 90-degree angle.

12.Ho amoheloa mofuta o khethehileng oa mofuta oa foreimi ea mofuta oa marako, 'me matla a susumetsang a fetohang a feto-fetoha ka lebelo le se nang mohato,' me lebelo le ka fetoloa ka mokhoa o ikemetseng ka har'a lebelo la 12-120 rpm.Tsamaiso e fetoha ho tloha holimo ho ea tlase, e ka fetoloang ho emulsification ea lisebelisoa tse fapaneng tsa viscosity.

13.Mofuta o khethehileng oa valve ea ho ntša tšepe e sa hloekang e tsamaisana le ho netefatsa hore ha ho na sekhutlo se shoeleng ka tlase ho pitsa, e leng ho ntlafatsang boleng ba homogenization le emulsification.

14.Sesebelisoa se fokotsang lebelo se sebelisa se fokotsang mabili a cycloidal pin 'me oli e tlotsang e nka 2L-2 lithium base grease.

15.'Mele oa pitsa ea emulsification ke mohaho oa likoti tse tharo,' me likarolo tsa pitsa e ka hare tse amanang le thepa li kenngoa ka ntle ho 304 le lisebelisoa tse se nang chefo le tse se nang kotsi ho netefatsa boleng ba lihlahisoa.Lera le ka ntle le tlatsitsoe ka k'hothone e thibelang mocheso ho fokotsa tšebeliso ea matla.Ho na le khalase ea pono le khalase ea "vacuum" e nang le sekheo holim'a sekoaelo sa pitsa, nkho ea linoko, sefe, mochini o lekanyang khatello, joalo-joalo.

16.Mesebetsi eohle e kang ho futhumatsa, ho pholisa, ho susumetsa, li-buttons tsa ho laola homogenization le lisebelisoa tsa ho lekanya mocheso li tsepamisitsoe holim'a phanele ea khabinete ea taolo, e loketseng le e ka tšeptjoang ho sebetsa.

17.Sesebelisoa sena se na le tsamaiso ea ho phahamisa li-hydraulic, ho phahamisa motlakase, ho bonolo ho sebetsa, ho ka emulsify thepa ka katleho tlas'a maemo a koetsoeng, e tsitsitseng e tloaelehileng ha e na mokhoa ona oa ho phahamisa.

18.Vacuum emulsifier e hlahisa theknoloji ea kantle ho naha 'me e entsoe ka botsebi ho latela mokhoa oa ho etsa litlolo le lihlahisoa tsa mafura.Setsi sena se na le pitsa ea pretreatment, vacuum homogenizing pitsa, pompo ea vacuum, sistimi ea haeteroliki, sistimi ea taolo ea motlakase le sethala se sebetsang.

19.Spiral ribbon scraping le ho kopanya ho ka etsa hore sehlahisoa se be bonolo ho kopanya, 'me katleho ea ho kopanya bonyane 2/3 e phahame ho feta ea ho kopanya foreimi e tloaelehileng;

20.Hlooho ea homogenizing e sebetsoa ke setsi sa machining se phahameng se nepahetseng ho etsa bonnete ba hore ho nepahala ho phahameng le litlhoko tse matla tsa ho leka-lekana.Ka matla a ts'oanang a matla, e ka hlahisa emulsion e ntle ea 2 ~ 5μm ho feta ea setso sa "gear ring dissperser;

21.Speed vacuum emulsifying lisebelisoa tsa ho kopanya li fanoa ka sistimi ea ho phahamisa khatello ea oli, e ka phahamisang le ho theola sekoaelo sa boiler ka bolokolohi mme e na le mesebetsi e joalo ka ho tilting ea boiler.

Tekheniki parameter:

| Mohlala | Bokhoni (L) | Matla a pitsa a maholo (kw) | Matla a pitsa ea metsi a oli (kw) | Matla a phahamisang metsi (kw) | Kakaretso ea matla(kw) | ||||||

| Tanka e kholo | Tanka ea metsi | Tanka ea oli | Ho kopanya motlakase | Enjene ea Homogenizer | Ho kopanya RPM | Homogenizer RPM | Ho futhumatsa mouoane | Ho futhumatsa motlakase | |||

| ZT-KB-150 | 150 | 120 | 75 | 1.5 | 2.2--4.0 | 0--63 | 0-3000 | 1.5 | 1.5 | 13 | 30 |

| ZT-KB-200L | 200 | 170 | 100 | 2.2 | 42.2--5.5 | 1.5 | 1.5 | 15 | 40 | ||

| ZT-KB-300 | 300 | 240 | 150 | 3.0--4.0 | 4.0--7.5 | 1.7 | 1.7 | 18 | 49 | ||

| ZT-KB-500 | 500 | 400 | 200 | 3.0--4.0 | 7.5--11 | 2.2 | 2.2 | 24 | 63 | ||

| ZT-KB-1000 | 1000 | 800 | 400 | 4.0--7.5 | 7.5--11 | 2.2 | 2.2 | 30 | 90 | ||

| HO FIHLELA 3000 |

|

| |||||||||

| Tlhokomeliso: Matla a motlakase a boholo ba mochini a ka etsoa ho latela lithupelo tsa bareki | |||||||||||

Kopo

Homogenization: emulsion ea meriana, setlolo, tranelate, mask a sefahleho, tranelate, homogenization ea lisele, sehlahisoa sa lebese homogenization, lero, enke ea khatiso, jeme:

(1) Indasteri ea letsatsi le letsatsi ea lik'hemik'hale le litlolo: tranelate ea tlhokomelo ea letlalo, tranelate ea ho kuta, shampoo, sesepa sa meno, tranelate e batang, setlolo se sireletsang letsatsi, se hloekisang sefahleho, mahe a linotši a phepo e nepahetseng, sesepa, shampoo, joalo-joalo.

(2), indasteri ea meriana: latex, emulsion, mafura (mafura), sirapo ea molomo, joalo-joalo.

(3), indasteri ea lijo: sauce e teteaneng, chisi, mokelikeli oa molomo, lijo tsa bana, chokolete, pheha tsoekere, joalo-joalo.

(4), indasteri ea lik'hemik'hale: latex, soso, lihlahisoa tsa saponification, pente, likoahelo, li-resin, likhomaretsi, li-detergents, joalo-joalo.

Khetho

1.phepelo ea matla: mekhahlelo e meraro: 220v 380v .415v.50HZ 60HZ

2.Matla: 100L ho isa ho 5000L

3.Letšoao la likoloi: ABB.Siemens khetho

4.Mokhoa oa ho futhumatsa: Khetho ea ho futhumatsa motlakase le ho futhumatsa mouoane

5.control system Key bottom bakeng sa esay run

6.Mofuta o tsitsitseng kapa mofuta oa ho phahamisa Hydraulic kapa ho phahamisa moea

7.mefuta e fapaneng ea meralo ea marang-rang e kopana le litlhoko tse fapaneng

8.Nomoro ea SIP e fumaneha ha o kopa ts'ebetso ea ho hloekisa

Video

-

hydraulic cylinder emulsion mixer mochiniI Cosm...

-

Mochini o kopanyang oa hydraulic cylinder emulsion mixer...

-

Emulsifier ea mofuta oa hydraulic lifting | Vacuu...

-

Ho potoloha ka hare le kantle ho emulsifying m...

-

Hydraulic lifting vacuum emulsifier ho kopanya mach...

-

Mofuta o tsitsitseng oa vacuum homogenizer mixer ski...