Product Description

1. All reaction is operated under a vacuum condition to prevent dust/microorganism contamination

2. Electric heating rod to heat the tank, automatic heating control is optional

3. With a cooling jacket for tank cooling. Easy operation. The jacket is wrapped by an insulation layer

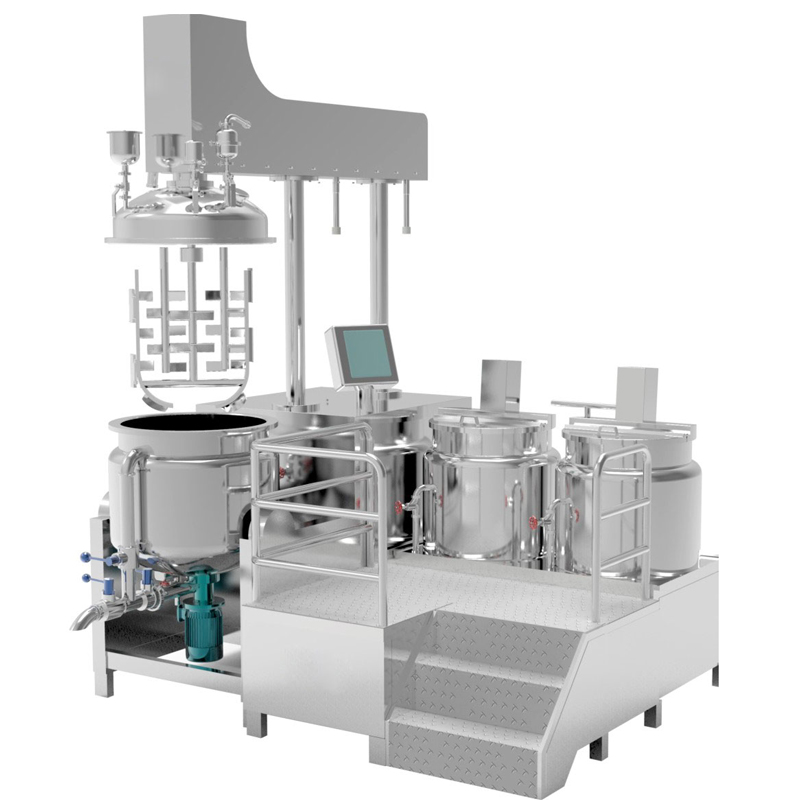

4. consist of main emulsifying mixer, water pot, oil pot, powder pot vacuum pump etc

5. Cosmetic production equipment adopts advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

6. High quality SUS304&316L material, internal and external mirror polish of homogenizer mixer.

7. High effection homogenizer, 2μm smooth finish 5) Sunflower oil making machine can also apply to cosmetics, pharmaceutical, food etc industries.

8. The pot cover is automatic rising type , the material was directed draw into the emulsifying pot from oil pot and water pot based on a pipe that is under vacuum ,

9. And the heating system is electric heating or steam heating that the temperature is automation

10. Cooling water can be used to cool in the interlayer, simple operation and safety (at the outside have a warm layer).

11. The homogenizer and the blade stirring can together work or separate work. the material sliming . emulsification .mixing .

12. Contact position adopt high-quality stainless steel (medical use adopt 316L material make with supplies ,

13. the polishing of the surface of the mirror of interior surface, mix the hygiene of the device in vacuum

14. accords with the normal hygiene standard of GMP to adopt that is most ideal production equipment).

15. One main vessel (dish head top, cone bottom, double jacketed non-pressure vessel (working under 0.095MPa), bottom homogenizer with external circulation, top entry anchor agitator with PTFE scrapers and toothed disk dispensers)

16. Two dissolving tanks (one double jacketed non-pressure vessel with both dish heads top and bottom, the other single layer with open flat cover and dish head bottom)

17. One powder pre-mixer (volume 0.5/0.8CBM, ribbon blender, fan included)

18. Siemens PLC controlled with HMI, full automatic with pneumatic valves

19.Burgmann mechanical seals, NOK oil seals, SpiraxSarco trap valves, Siemens motors with Panasonic inverters.

20. Hydraulic lifting system to open the cover, NASH-elmo vacuum pump working under -0.097MPa (-0.095MPa typical).

21. Steam heating and water cooling ( just pipework included, cooling with chilled water is preferred, 2-step cooling in this case),

22. Rotor pump for discharging, platform for the machine to working o

Technical parameter

| Model | Capacity(L) | dispersing motor no2 | scraper stirring motor | Power pot motor | Limited vacuum (Mpa) | Size (mm)L*W*H | ||||||

| Main pot | Oil pot | Water pot | Powder pot | KW | RPM | KW | RPM | kw | rpm | |||

| 100 | 100 | 50 | 80 | 100 | 3 |

1440

|

1.5 |

0-63 |

0.75 |

1440 |

-0.095 |

2485*2600*200-2900 |

| 200 | 200 | 100 | 160 | 200 | 4 | 2.2 | 1.1 | 2750*3000*2400-3100 | ||||

| 500 | 500 | 250 | 400 | 500 | 5.5 | 4 | 2.2 | 3500*3500**3900 | ||||

| 1000 | 1000 | 500 | 800 | 1000 | 5.5 | 5.5 | 2.2 | 3700*4200*4600 | ||||

| 2000 | 2000 | 1000 | 1600 | 2000 | 7.5 | 11 | 3 | 4300*4800*5400 | ||||

Option

1. power supply: three phase : 220v 380v .415v. 50HZ 60HZ

2. Capacity : 100L up to 5000L

3. Motor brand : ABB. Siemens option

4. Heating method: Electric heating and steam heating option

5. control system plc touch screen. Key bottom

6. Fixed type or Hydraulic lifting type or Pneumatic lifting

7.variety of paddle designs meet difference requirement

8.SIP is available upon request for cleaning process