Our firm promises all consumers from the first-class solutions along with the most satisfying post-sale company. We warmly welcome our regular and new clients to join us for Renewable Design for Ailusi Bench Top Round Glass Jar Cans Wine Bottle Sticker Automatic Essential Oil Bottle Labeling Machine for Round Bottles, Therefore, we can meet different inquiries from different clients. Please find our website to check more information from our products.

Our firm promises all consumers from the first-class solutions along with the most satisfying post-sale company. We warmly welcome our regular and new clients to join us for China Food Packaging and Food Packaging Machines, When It produced, it making use of the world’s major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a “people-oriented, meticulous manufacturing, brainstorm, make brilliant” company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we’ll be delighted to serve you.

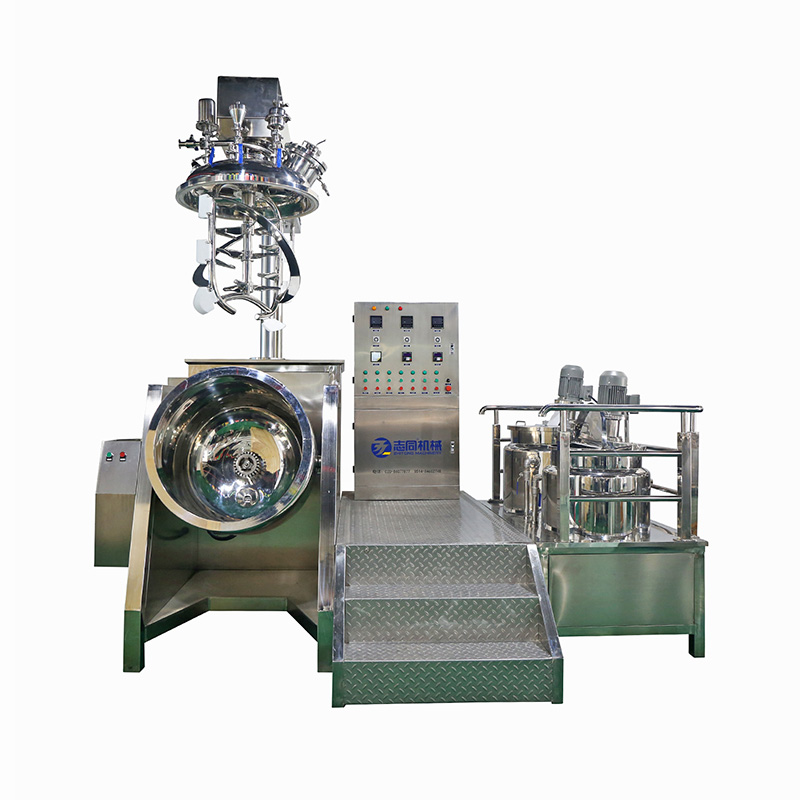

Product Description

1.Cosmetic Machinery Complete process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit;

2.Cooling system for mechanic seal inside the homogenizer for longer homogenizing time;

3.Full system has process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit individually functions;

4.Cosmetic Machinery is Variable speed for homogenizer1-3000R/min and agitator 1-63R/min.

5.Cosmetic Machinery Complete process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit;

6.Cooling system for mechanic seal of Cosmetic Machinery inside the homogenizer for longer homogenizing time;

7..Full system has process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit individually functions;

8.Variable speed for homogenizer1-3000R/min and agitator 1-63R/min;

9.Complete process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit;

10.Cooling system for mechanic seal inside the homogenizer for longer homogenizing time;

11.Full system has process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit individually functions;

12.Cosmetic Machinery is Variable speed for homogenizer1-3000R/min and agitator 1-63R/min;

13.The emulsifying effect is more prominent for materials of high base viscosity and high solid content.

14.The main pot has many accessories, with feeding monitoring emulsification and other functions.The relevant configuration is carried out.

15.Cosmetic Machinery Oil and water pot materials enter the homogenizer directly through the proportional valve can save time and improve efficiency.

16.Bottom homogenization mode: The bottom homogenization is 0-3000 RPM, variable frequency speed regulation, emulsification is more complete and thorough, and the product is exquisite.

17.Oil pot, water pot: Equipped with heating and dispersing functions, the material can be pretreated with heating, dispersing and stirring to disperse at 960 RPM

18.The triple mixing adopts the imported frequency inverter for speed adjustment,which can meet different technological demands.

19.According to process requirement, Cosmetic Machinery the tank body can heating and cooling the electric heating.

20.Three-layers stainless steel tank. The tank uses high-quality SS316 material, which has the features of anti-corrosion, acid resistance, antioxidant, glossy and valuable. After 320 mesh grinding polishing, it can both reach the standard of GMP and has an attractive appearance.

21.The boiler body is welded with 3 layer imported SS plate, tank body and pipes adopts mirror polish whcih meet the GMP standard.

22. One way stirring, two-way stirring, screw belt two-way stirring,screw belt one-way stirring, anchor mixing variable frequency speed regulation, 0-63 RPM, teflon scraper, at any time to cater to the shape of the stirring tank, scraping the pot wall sticky material.

23.The main boiler lid can adopt lifting system, it is easy to clean and the cleaning effect is more obvious, the main boiler can adopt tilting discharge.

24.The vacuum material of Cosmetic Machinery sucking is adopted, and especially for the powder materials, vacuum sucking can avoid dust to keep the purity.

25.The vacuum defoaming can make the materials meet the requirement of being aseptic . The vacuum materials vacuum sucking can avoid dust.

26. Vacuum emulsifier main pot:Main pot hydraulic lifting.three layers of stainless steel structure, can be manually tipped out. Equipped with material inlet, vacuum gauge, vacuum valve, view mirror, air filter, perfume hopper and so on.

27.lift of Cosmetic Machinery overall mixing system to the outside of the pot, which is easy to clean and observe.

28.The control system is fully automatic. Touch screen, timer and process recorder are parts of control features.

29.Cosmetic Machinery With vacuum system, the pot can be maintained at a vacuum of less than -0.095MPa.

30.The raw material could be sucked into this mixer directly by vacuum function0 Inverter and electrical control box.

31.Burgmann mechanical seal, water circulation cooling, cooling and homogenizer synchronization, NSK bearing, Siemens motor, Panasonic frequency inverter.

32.The two pretreatment pots are both equipped with independent heating, temperature control and dispersing system. Pretreament materials can be directly sucked into main pot via negative pressure of main pot.

Technical parameter:

|

Model |

Capacity(L) |

Emulsify motor |

Mixing motor |

Toal power (steam/electric heating ) |

Limited vacuum (Mpa) |

Size (mm) L*W*H |

||||

|

Main pot |

Oil pot |

Water pot |

KW |

RPM |

KW |

RPM |

||||

|

50 |

50 |

25 |

40 |

2.2 |

0-3000 |

0.75 |

0-63 |

8/30 |

-0.09 |

2185*2500*200–2650 |

|

100 |

100 |

50 |

50 |

4 |

1.5 |

10/37 |

2385*2600*200-2900 |

|||

|

150 |

150 |

100 |

120 |

5.5 |

2.2 |

12/40 |

2650*3000*2400-3100 |

|||

Application

Homogenization: medicine emulsion, ointment, cream, facial mask, cream, tissue homogenization, milk product homogenization, juice, printing ink, jam paint ink: latex paint, interior and exterior paint, water-based paint, nano paint, paint additives, ink, ink, textile dyes, pigments, etc. 5, biomedicine: sugar coating, protein dispersant, medicine cream, etc. herbicide, pesticide oil, pesticide additives, fertilizer, etc.

Option

Video

Our firm promises all consumers from the first-class solutions along with the most satisfying post-sale company. We warmly welcome our regular and new clients to join us for Renewable Design for Ailusi Bench Top Round Glass Jar Cans Wine Bottle Sticker Automatic Essential Oil Bottle Labeling Machine for Round Bottles, Therefore, we can meet different inquiries from different clients. Please find our website to check more information from our products.

Renewable Design for China Food Packaging and Food Packaging Machines, When It produced, it making use of the world’s major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a “people-oriented, meticulous manufacturing, brainstorm, make brilliant” company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we’ll be delighted to serve you.

-

Factory Cheap Chemical Storage Tank Price Stain...

-

Wholesale Small Lab Mixer Homogenizer, High She...

-

2019 China New Design Mustard, Mayonnaise Makin...

-

Wholesale price in Short Supply Double Jacketed...

-

Quoted price for Factory Price Jacketed Cosmeti...

-

OEM Customized Facial Cream Body Lotion Hand Sa...