Sticking to the principle of “Super Quality, Satisfactory service” ,We are striving to be a good business partner of you for Quality Inspection for Good Price Pharmaceutical Ointment Cream Mixer Machine Cosmetic Vacuum Emulsifying Toothpaste Making Equipment, Trust us and you will gain a lot more. You should truly feel totally free to make contact with us for additional data, we assure you of our greatest notice at all times.

Sticking to the principle of “Super Quality, Satisfactory service” ,We are striving to be a good business partner of you for China Vacuum Emulsifying Toothpaste Mixer and Industrial Toothpaste Making Equipment, We also supply OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best goods for our customers.

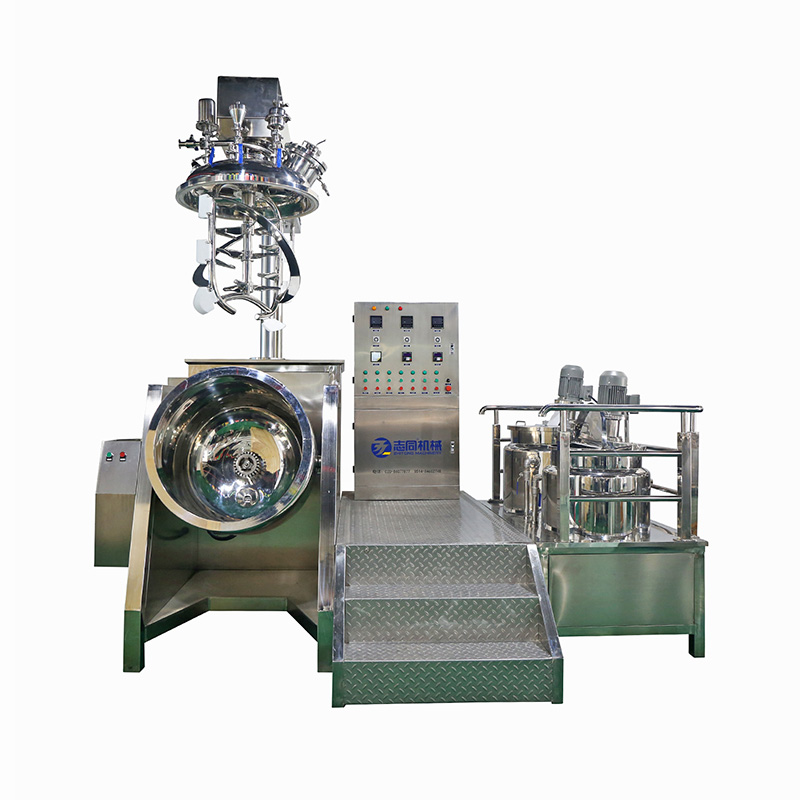

Product Description

1.The Cosmetic Manufacturing Equipment adopts lifting system, easy to clean with CIP ball and the cleaning effect is more abvious, the emulsifying pot can adopt tilting discharge

2. Suitable for cream and emulsion of 10,000~180,000cps viscosity

3. The homogenizer and the blades stirring can together work or separate work

4. This Cosmetic Manufacturing Equipment vacuum mixer tank adopts double-direction wall scraping blending and frequency conversion speed adjustment to satisfy different technological requirements.

5. With adopts lifting system, easy to clean with CIP ball and the cleaning effect is more abvious for Cosmetic Manufacturing Equipment , the emulsifying pot can adopt tilting discharge.

6. Cosmetic Manufacturing Equipment is Suitable for cream and emulsion of 10,000~180,000cps viscosity.

7. The homogenizer and the blades stirring can together work or separate work.

8. Scraping unit is with moveable teflon scrapers to scrape off the materials on the tank wall and the anchor to move the materials to the center area to get better blending and mixing. The teflon scrapers are maintained manually and easily without any tool.

9. All contacted parts of equipments are SUS316L,the product homogenized in vacuum and close vessel can be sanitary and high quality.

10. Polytetrafluroethylene scraping board cater to body of blending groove and scrape out viscosity material on boiler wall;

11. Cosmetic Manufacturing Equipment has homogenizer also works as a transfer pump for discharging finished product; Save one transfer pump for budget;

12.The specifications of the Cosmetic Manufacturing equipment comply with GMP regulations;

13. The multi-layer rotor produces a strong suction force to suck the material into the working cavity.

14.Cosmetic Mixer lifting is convenient for homogenous in the closure condition and make the vacuum level (-0.095mpa).

15. centrifugal to make sure exquisite and slick cream; boiler body and pipe surface mirror polishing 300EMSH (sanitation grade) accords with Daily Chemical and GMP regulation.

16. Complete Cosmetic Mixer process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit for easy to operate.

17. 45 degree inclined blade ,ensures material rolling and stirring effect Seamless welding , easier to clean after production for better machine performance.

18. buttons control panel for easy operation and cost down.

19. Double temperature probes of Cosmetic Mixer and controllers for electrical heating in main emulsifying mixer;

20. the material is in a vacuum state during the whole production process in the Cosmetic Mixer , making the material fine and without bubbles.

21. The blending system of the vacuum emulsifying mixing equipment adopts advanced triple blending and frequency conversion speed adjustment, so ads to satisfy production of different technology requirement.

22 The stator and rotor of the homogenous head are tightly coupled, 1-2mm. One-time casting to finalize the mold.

Technical parameter:

|

Model |

Capacity (L) |

Main pot power (Kw) |

Oil water pot power (Kw) |

Hydraulic lift power (Kw) |

Total power(kw) |

||||||

|

|

Main tank |

Water tank |

Oil tank |

Mixing motor |

Homogenizer motor motor |

mixing RPM |

homogenizer RPM |

|

|

steam heating |

Electrical heating |

|

ZT-KB-150 |

150 |

120 |

75 |

1.5 |

2.2–4.0 |

0-63 |

0-3000 |

1.5 |

1.5 |

13 |

30 |

|

ZT-KB-200L |

200 |

170 |

100 |

2.2 |

2.2–5.0 |

1.5 |

1.5 |

15 |

40 |

||

|

ZT-KB-300 |

300 |

240 |

150 |

2.5 |

4.0–11 |

1.7 |

1.7 |

18 |

49 |

||

|

ZT-KB-500 |

500 |

400 |

200 |

4 |

5.0–11 |

2.2 |

2.2 |

24 |

63 |

||

|

ZT-KB-1000 |

1000 |

800 |

400 |

5.5 |

7.5–11 |

2.2 |

2.2 |

30 |

90 |

||

|

UP TO 3000 |

|

|

|

|

|||||||

|

Remark: The machine dimensioon motor power can be customized according customers workshop |

|||||||||||

Application

Homogenization: medicine emulsion, ointment, cream, facial mask, cream, tissue homogenization, milk product homogenization, juice, printing ink, jam:

food industry: chocolate shell, fruit pulp, mustard, slag cake, salad sauce, soft drinks, mango juice, tomato pulp, sugar solution, food essence, additives, etc.

8, nanomaterials: nano calcium carbonate, nano coatings, all kinds of nano material additives, etc.

Option

Video

Quality Inspection for China Vacuum Emulsifying Toothpaste Mixer and Industrial Toothpaste Making Equipment, We also supply OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best goods for our customers.

-

China Wholesale Mini Bar Soap Making Machine, P...

-

2019 China New Design Mustard, Mayonnaise Makin...

-

100% Original Mixer Tank for Blending Fertilize...

-

OEM Factory for Vacuum Homogenizing Emulsifying...

-

Well-designed Jacketed Stainless Steel Industri...

-

ODM Manufacturer Jinzong 1000L Shampoo Mixer Va...