We now have one of the most advanced production machines, experienced and qualified engineers and workers, regarded quality manage systems and a friendly skilled sales group pre/after-sales support for Big discounting Equipment Mixer for Creams Emulsifier Machine Homogenizing Vacuum Maker Homogeneous Cream Cosmetic Manufacturing Production Line, If you are fascinated in any solutions, you should experience absolutely free to make contact with us for additional details or you should send out us email instantly, we will reply you within just 24 hours and also the best quotation might be provided.

We now have one of the most advanced production machines, experienced and qualified engineers and workers, regarded quality manage systems and a friendly skilled sales group pre/after-sales support for China Homogenizer Vacuum Mixer and Vacuum Mixer, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for yourself always.

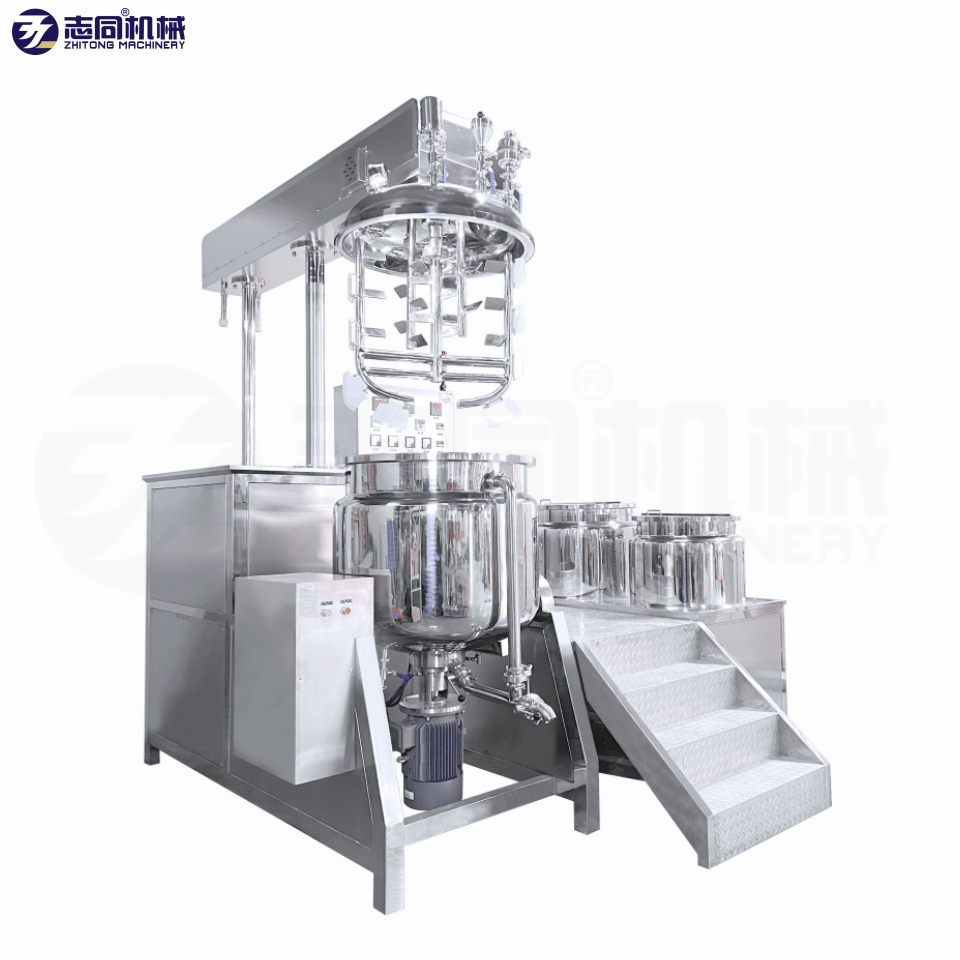

Product Description

1.Lifting emulsifier, including emulsifying pot , operating platform, oil and water pot , oil and water pot and controller; Emulsifying pot device including emulsifying pot, emulsifying pot rack and emulsifying pot cover fixed plate, emulsifying pot set on mixing mechanism, dumping, cooling circulation mechanism, vacuum institutions and emulsifying pot cover lifting mechanism, mixing, dumping, cooling cycle machine, vacuum institutions and emulsifying pot cover the controlled end of the lifting mechanism is connected to the output of the controller.

2.Working capacity from 200L up to 2000L;

3.Suitable for high viscosity material of 10,000~180,000cps viscosity;

4.Homogeneous stirring and paddle stirring can be used separately or at the same time. Material granulation, emulsification, uniform mixing, dispersion, etc. can be completed in a short time;

5.The entire process is carried out under vacuum conditions to prevent the material from generating bubbles after high-speed stirring, and can meet the requirements of sanitation and sterility;

6. .The rotor of the powerfully balanced special curve is matched with the stator of the corresponding structure to achieve fluid, high-energy shearing, milling, and centrifugation, so as to ensure the fineness of the paste.

7.Three-layer stainless steel structure of the pot body, mirror polished, fully in line with GMP requirements;

8.Variable speed for homogenizer and agitators in both main emulsifying kettle and oil and water mixers;

9.The homogenizer also works as a transfer pump for discharging finished product;

10.Variable speed for homogenizer er and agitators in both main emulsifying kettle and oil and water mixers;

11.Double jackets for heating and cooling; Agitating system has the window and light.

12.Stirring and homogenization adopt imported frequency converter to meet the requirements of different production processes;

13.Complex scraping board blending oar is suitable to every kind of complicated recipe and achieve optimizing effect;

Mightiness balance isotactic curve rotor is matched with stator with corresponding structure to realize liquid high-capability cut,rubbing,

14.Vacuum defoaming to make the material meet the sterility requirements, vacuum suction (water, oil, powder) can be used.

15.Homogenizer is installed on boiler bottom to increase motor power more thoroughly and strongly. During few production, it can exert homogenizing effect fully;

16.Tanks’ material adopts high-quality domesticSUS304 and SUS 316.

17.Different jacket designs available for steam and electric heating for more customers option;

18.Double temperature probes and controllers for electrical heating in main vacuum homogenization blender insure more accuracy Vacuum system to take out the air bubbles during mixing and to transfer the ingredients;

19.Homogenizing vacuum emulsifier mixer can choose frequency conversion timing homogenizer and highest rotate speed is 4500 r/min;

20. Perfect particle size of 2 micrometers and evenly distributed;

21. Double jackets for heating and cooling with good cooling and heating process to save cost.

Technical parameter:

| Model | Capacity(L) | Emulsify motor | Mixing motor | Toal power(steam/electric heating ) | Limited vacuum (Mpa) | Size (mm)L*W*H | ||||

| Main pot | Oil pot | Water pot | KW | RPM | KW | RPM | ||||

| 150 | 150 | 75 | 120 | 7.5 | 0-3000 | 1.1 | 0-63

|

13/30 | -0.09 | 2180*2500*26500*–2700 |

| 200 | 200 | 160 | 50 | 7.5 | 1.5 | 15/40 | 2380*2600*200-2900 | |||

| 300 | 300 | 240 | 160 | 11 | 2.2 | 18/49 | 3000*3400*2500-3600 | |||

| 500 | 500 | 400 | 400 | 11 | 4 | 24/63 | 3400*3500*2900-3900 | |||

| 1000 | 1500 | 800 | 800 | 15 | 5.5 | 30/90 | 3600*4200*3300-4600 | |||

| 2000 | 2000 | 1000 | 1600 | 18.5 | 7.5 | 40/120 | 4200*4800*3800-5400 | |||

Application

cosmetics, food, medicine, plastic resin, printing and dyeing, printing ink, asphalt and other industries have a wide range of applications.

1, fine chemicals: plastics, fillers, adhesives, resins, silicone oil, sealants, slurry, surfactants, carbon black, defoaming agent, brightener, leather additives, coagulants, etc.

2, petrochemical industry: heavy oil emulsification, diesel oil emulsification, lubricating oil, etc.

3, daily chemical industry: washing powder, concentrated washing powder, liquid detergent, all kinds of cosmetics, skin care products, etc.

Option:

Video

We now have one of the most advanced production machines, experienced and qualified engineers and workers, regarded quality manage systems and a friendly skilled sales group pre/after-sales support for Big discounting Equipment Mixer for Creams Emulsifier Machine Homogenizing Vacuum Maker Homogeneous Cream Cosmetic Manufacturing Production Line, If you are fascinated in any solutions, you should experience absolutely free to make contact with us for additional details or you should send out us email instantly, we will reply you within just 24 hours and also the best quotation might be provided.

Big discounting China Homogenizer Vacuum Mixer and Vacuum Mixer, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for yourself always.

-

Factory Outlets Vacuum Automatic Emulsification...

-

Well-designed Ave-100L High Shear Mixer Face Cr...

-

factory low price Lab Laboratory Cream Mixer Em...

-

Professional China Manufacturer Supply Drinking...

-

Pneumatic Sus High Speed Lifting Disperse Paint...

-

Top Suppliers Mayonnaise Sauce Food Vacuum Emul...